Subtotal: €0,00

USED MULTI-SPINDLE LATHE GILDEMEISTER GM20-6 AC WITH STANDARD PIETRO CUCCHI LOADER ** Technical details of the lathe ** Model: Gildemeister GM20-6 AC Year: 2003 Serial number: 4502-0446 Accessories supplied: 1x set of front spindles with ISO30 connection (2 rotating + 3 fixed) 1x hydraulic chuck in pos.6 1x double mechanical cutting and reworking slide in pos.6 1x slide with micrometric axial adjustment in pos.3 2x independent axial control (cam excluded) in pos.1-2 5x turret + Bar tool holder for radial carriages 1x Thread clutch unit (tapping) 1x Metal chute with pneumatic control for output Pcs 1x High pressure coolant line predisposition 1x Removable internal tank with screw chip conveyor CE certification Mechanical overhaul which includes: replacement of drum bearing line, complete replacement of the collet closure, alignment of the central block, boring of the spindle supports, replacement of wagon gibs ** Technical details of the loader ** Model: Pietro Cucchi standard Serial number: 101B04 Year: 2004 Type: Loader with side bar magazine ** Download data sheet ** GM20-6AC_4502-0446_2003.pdf

SOLD *** USED MULTI-SPINDLE LATHE GILDEMEISTER GM20-6 AC v.25 mm WITH SHELL AND TUBE AND POST ** Technical details of the lathe ** Model: Gildemeister GM20-6 AC v.25 mm Year: 1995 Serial number: 3103-0150 Accessories supplied: 5x front spindles 1x hydraulic chuck in pos.6 2x independent axial controls (cams excluded) in pos.1-2 5x turret + tool holder for radial carriages 1x clutch group thread (tapping) 1x metal chute with pneumatic control for Pcs outlet 1x External tank for oil settling 1x Screw chip conveyor 1x Tube bundle with CE certification post ** Download data sheet ** GM20-6AC_V25_3103-0150_1995.pdf

*** VENDUTO *** TORNIO PLURIMANDRINO USATO GILDEMEISTER GM20-6 AC v.25 mm CON FASCIO TUBIERO E PIANTANA ** Dettagli tecnici del tornio ** Modello: Gildemeister GM20-6 AC v.25 mm Anno: 1996 Matricola: 3103-0235 Accessori a corredo: 5x mandrini frontali 1x mandrino da ripresa idraulico in pos.6 1x slitta con registrazione assiale micrometrica in pos.3 3x comandi assiali indipendenti (camme escluse) in pos.1-2-5 5x torretta + portautensile per carri radiali 1x gruppo frizioni filettatura (maschiatura) 1x scivolo per uscita pz + 1x separatore pneumatico per pz non conformi 1x vasca esterna per decantazione olio 1x evacuatore trucioli a coclea 1x fascio tubiero con piantana certificazione CE ** Download scheda tecnica ** GM20-6AC_V25_3103-0235_1996.pdf

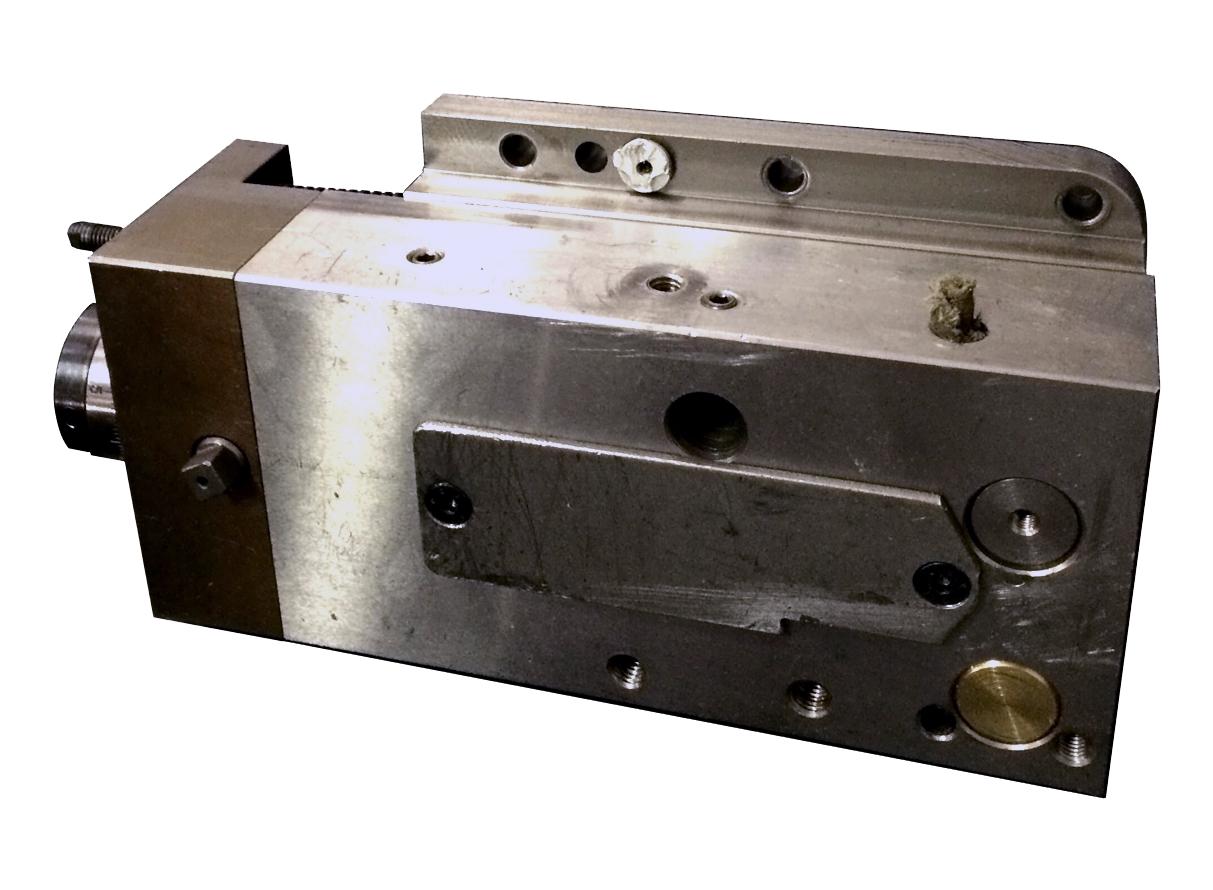

USED RADIAL SLIDE FOR GILDEMEISTER GM20 POS. 6TH

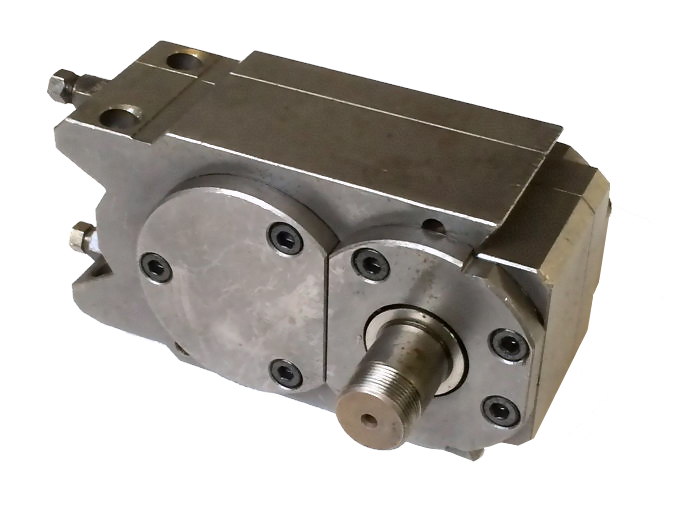

G1D/0 THREAD-MILLING/POLYGONAL GRIPPER BOX USED FOR GILDEMEISTER AS20-GS20-GM20 The box has two gripper outlets, thus allowing two devices mounted in the POS to be served at the same time. 4th and 5th. The two presamoto outputs will have respectively: – a 1:1 ratio for milling threads (1 turn of the cutter corresponds to 1 turn of the presamoto shaft), – a 2:1 ratio for making polygons (2 turns of the cutter correspond to 1 turn of the presamoto shaft).

G1D/2C THREAD MILLING CUTTER BOX USED FOR GILDEMEISTER AS20-GS20-GM20 The box has a milling cutter shaft with cylindrical Ø18 connection, and has a 1:1 ratio for milling threads (1 turn of the cutter corresponds to 1 turn of the crankshaft). Completed with an adaptation plinth, it can be positioned indifferently in the POS. 4th or 5th. On request, the box can be supplied: – with a cutter spindle with 8° 32′ conical attachment, instead of the cylindrical one, – completely overhauled.

G1D/2B POLYGONAL CUTTER BOX USED FOR GILDEMEISTER AS20-GS20-GM20 The box has a cutter spindle with 8° 32′ conical attachment, and has a 2:1 ratio for milling polygons (2 revolutions of the cutter correspond to 1 revolution of the presamotion shaft). Completed with an adaptation plinth, it can be positioned indifferently in the POS. 4th or 5th. On request, the box can be supplied: – with a cutter shaft with cylindrical attachment, instead of the 8° 32′ conical one, – completely overhauled.

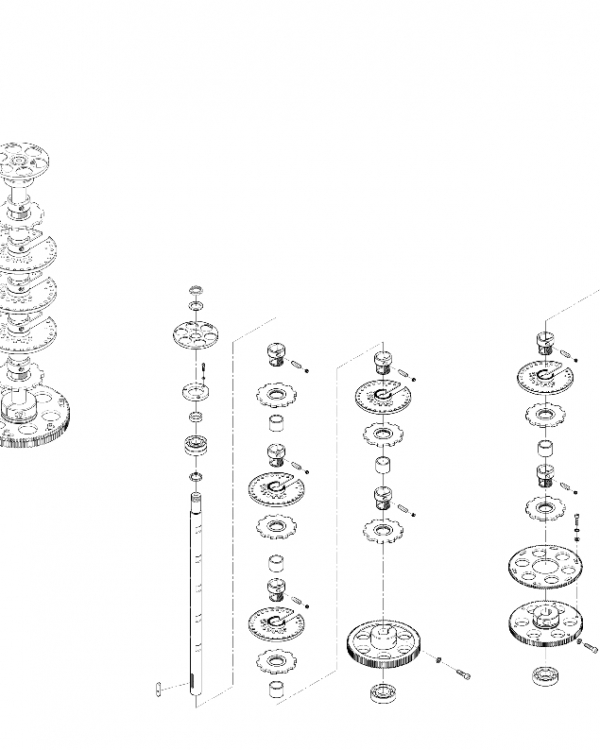

5309002 - RIGHT-HAND DOVE SHAFTS

5309002 - RIGHT-HAND DOVE SHAFTS