USED MULTI-SPINDLE LATHE GILDEMEISTER GM32-6 v.35 mm SPINDLE STOP WITH INTRODUCER IEMCA PRA 40-33P ** Technical details of the lathe ** Model: Gildemeister GM32-6 v.35 mm spindle stop Year: 1992 Serial number: 3701-179 Supplied accessories: 5x turret + tool holder for radial carriage 5x front spindles 1x hydraulic chuck in pos.6 1x hydraulic chuck in pos.6 1x threading unit 1x workpiece gripper in pos.6 1x metal chute with pneumatic control for 1x external tank for oil settling 1x screw chip conveyor 1x tube bundle with stand ** Technical details of the loader ** Model: IEMCA 40-33P Serial number: 92013102 Year: 1992 Type: Introducer ** Download data sheet ** GM32-6_V35_s-m_ 3701-179_1992.pdf

USED MULTI-SPINDLE LATHE GILDEMEISTER GM35-6 WITH SHELL AND TUBE AND POST ** Technical details of the lathe ** Model: Gildemeister GM35-6 Year: 1996 Serial number: 4901-117 Accessories supplied: 5x turret + tool holder for radial carriages 5x new type front spindles with ISO40 connection 1x hydraulic chuck in pos.6 1x hydraulic chuck in pos.6 1x hydraulic power unit to control the chuck and the chuck 2x independent axial slide with holes M12 threaded in pos.1-4 2x independent axial control (cams excluded) in pos.1-4 1x external tank for oil settling 1x screw chip conveyor 1x tube bundle with CE certification post ** Download data sheet ** GM35-6_4901-117_1996.pdf

*** VENDUTO *** TORNIO PLURIMANDRINO USATO GILDEMEISTER GM35-6 HIRT CON FASCIO TUBIERO E PIANTANA ** Dettagli tecnici del tornio ** Modello: Gildemeister GM35-6 AC Hirt Anno: 2005 Matricola: 4903-0220 Accessori a corredo: 5x torretta + portautensile 5x mandrini frontali tipo nuovo con attacco ISO40 1x mandrino da ripresa idraulico in pos.6 1x slitta idraulica da ripresa in pos.6 1x centralina idraulica per comandare il mandrino da ripresa e la slitta da ripresa 2x slitta assiale indipendente con fori filettati in pos.1-4 2x comando assiale indipendente (camme escluse) in pos.1-4 1x vasca esterna per decantazione olio 1x evacuatore trucioli a coclea 1x fascio tubiero con piantana certificazione CE ** Download scheda tecnica ** GM35-6_4903-0220_2005.pdf

USED GILDEMEISTER GM35-8 MULTI-SPINDLE LATHE WITH PIETRO CUCCHI AN-BN LOADER ** Technical details of the lathe ** Model: Gildemeister GM35-8 Year: 1999 Serial number: 4201/0115 Accessories supplied: 4x turret + tool holder for pos.2-3-6-7 2x cutting tool holder for pos.4-8 6x rotating front spindle in pos.1-2-3-5-6-7 2x hydraulic spindle in pos.4-8 1x hydraulic power unit for re-spindle 2x brake for re-spindle in pos.4-8 1x thread clutch assembly (tapping) 4x independent axial slide in pos.2-3-6-7 2x bar stop control in pos.1-5 2x workpiece gripping paddle with pneumatic control in pos.4-8 2x chute for workpiece exit in pos.4-8 1x basket for collecting scrap pieces 1x set of cams (17 pcs) 1x removable inner tank with screw chip conveyor Logbooks CE certification ** Technical details of the loader ** Model: Pietro Cucchi AN-BN Serial number: 197B99 Year: 1999 Type: Charger ** Download data sheet ** GM35-8_4201-0115_1999.pdf

ORIGINAL USED PNEUMATIC CHUCK FOR GILDEMEISTER AS67

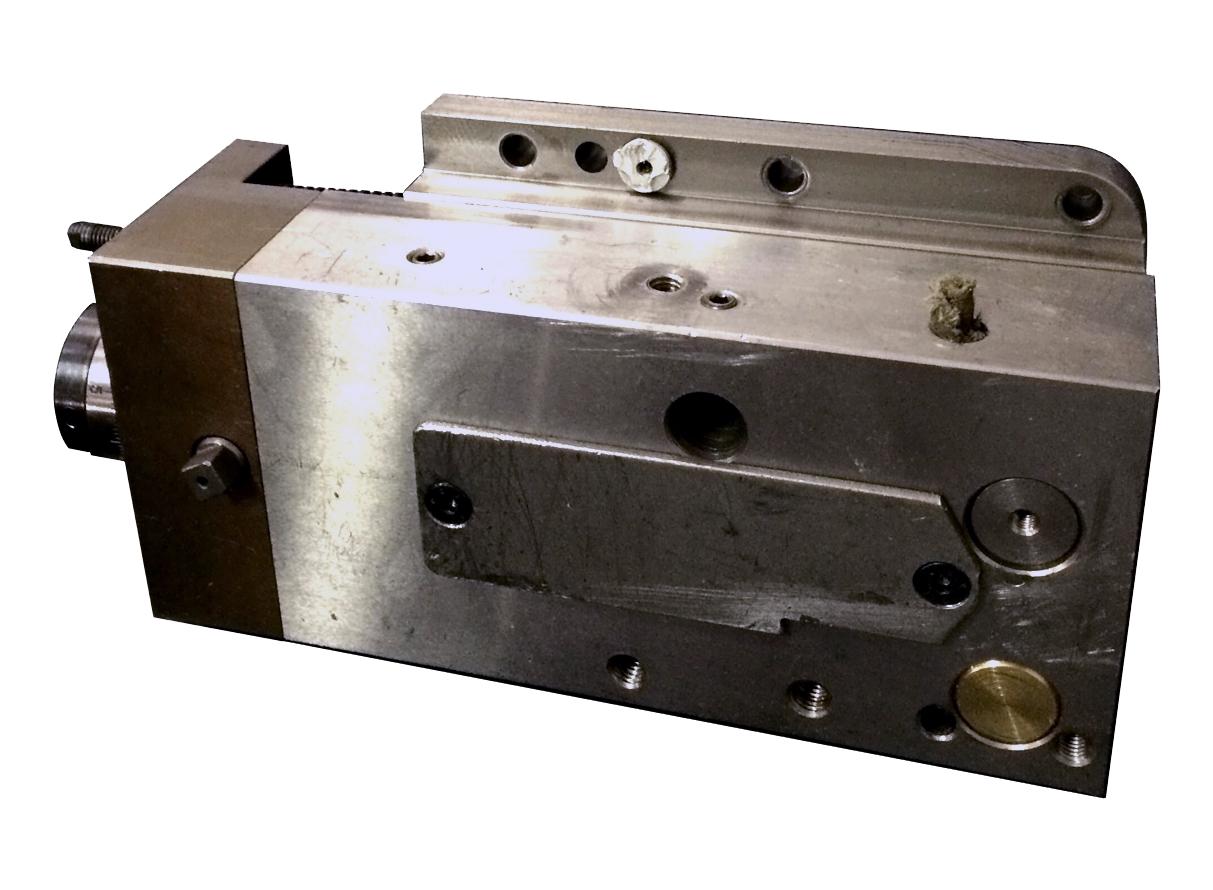

USED SHAVING TOOL-HOLDER FOR GILDEMEISTER AS16/AS20

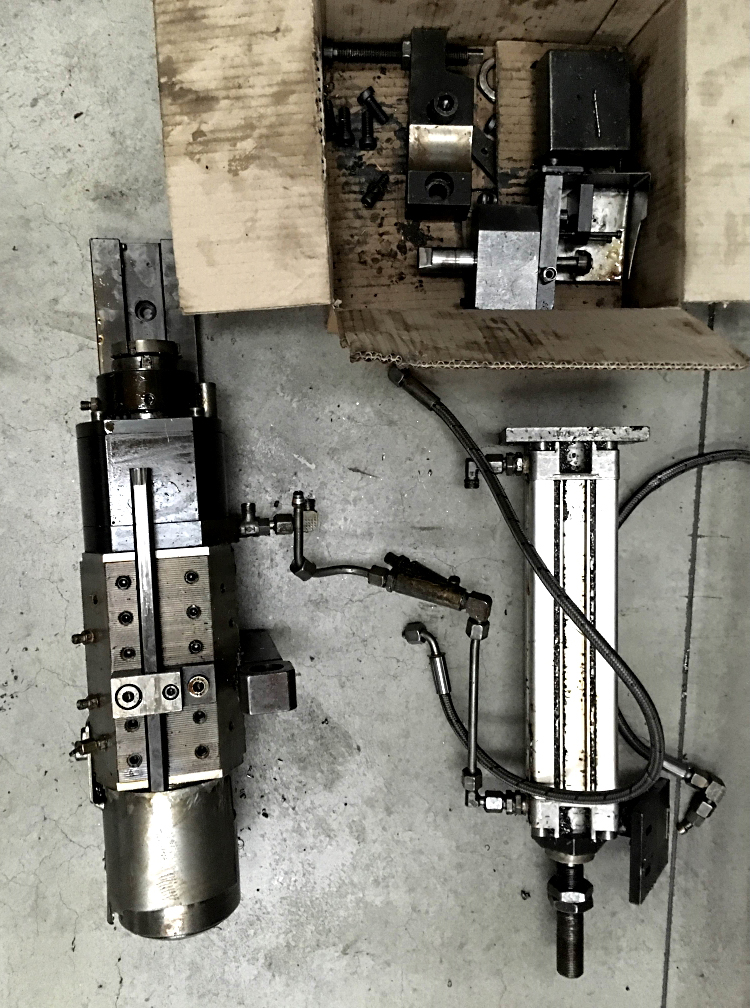

USED RADIAL SLIDE FOR GILDEMEISTER GM20 POS. 6TH

ORIGINAL USED PNEUMATIC CHUCK FOR GILDEMEISTER AS48

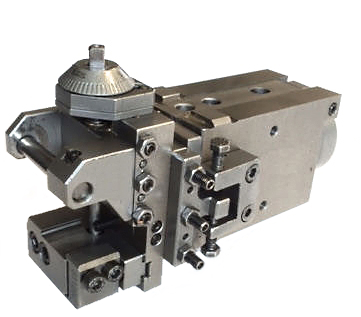

G1D/0 THREAD-MILLING/POLYGONAL GRIPPER BOX USED FOR GILDEMEISTER AS20-GS20-GM20 The box has two gripper outlets, thus allowing two devices mounted in the POS to be served at the same time. 4th and 5th. The two presamoto outputs will have respectively: – a 1:1 ratio for milling threads (1 turn of the cutter corresponds to 1 turn of the presamoto shaft), – a 2:1 ratio for making polygons (2 turns of the cutter correspond to 1 turn of the presamoto shaft).